OLIS USA Stopped-flow Mixing Device

Download Specifications

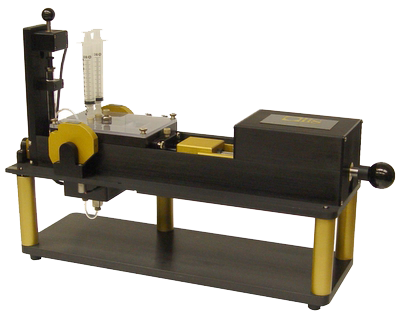

Useful. Simple. Affordable. A two syringe design for millisecond mixing of reactants.

Absorbance, fluorescence, and circular dichroism are useful tools for monitoring kinetic changes of chemical and biological systems. However, changes often occur on the millisecond scale, too fast for manual mixing. A stopped-flow accessory is used to automate mixing with extreme precision. Reagents are injected from two drive syringes through a mixer into the observation cell, where the changes in absorbance, fluorescence, or circular dichroism are recorded. Reactions can be studied with the stopped-flow method ranging from a few milliseconds to hundreds of seconds.

Features:

Failsafe operations. It literally cannot be misfired.

Low volume per shot, easily adjustable

True millisecond deadtime, even with high viscosity samples

Designed as an accessory to a host spectrophotometer; easy to add and remove

Introduce degassed solutions by way of gastight tonometers

Standard model range -5° to 100°C; low-temperature variant -50 to +5°C

Ceramic valves, used because ceramic is inert, impervious to temperature extremes, and 99% the hardness of diamonds. No one has ever damaged a valve on an OLIS stopped-flow!

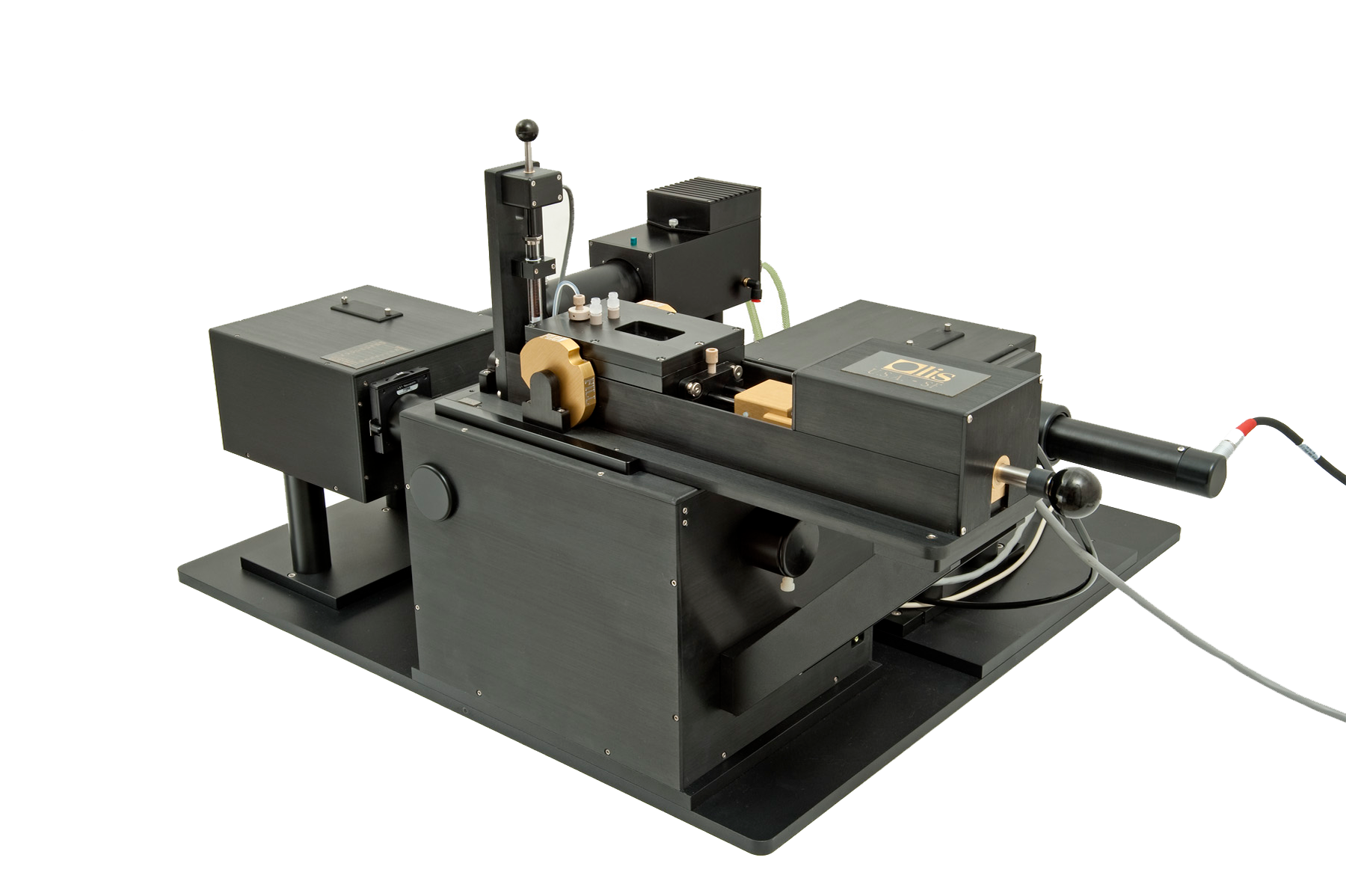

RSM 1000 SF and tonometers

The OLIS RSM 1000 with OLIS USA stopped-flow fitted with tonometers for ease in introducing degassed solutions into the stopped-flow. “Tonometers” are the gastight columns with stopcocks for hooking to nitrogen or argon lines for purging. They function as the “full syringes,” loading the “drive syringes” with sample. The metal arms hold these tonometers in place.

A “stopped-flow” was the first hardware produced at OLIS, dating to 1992. Prior to then, we had computerized stopped-flows produced by American, British, French, and Japanese manufacturers. But, each of these third-party products had weaknesses which their manufacturers did not resolve or bells & whistles we thought were unnecessary. So, we developed our own to be “useful, simple, and affordable.”

Attributes unique to the OLIS stopped-flow include (1) use of ceramic valves, which is hugely effective in eliminating aging and subsequent leaking of the key junction points within the mixer (the valves), and (2) sensors on the syringes, fill-flow valves, and pneumatic drive so that misfiring of the stopped-flow is impossible. (Too many people – using non-OLIS stopped-flows – have “lost all your enzyme, because the stopped-flow let me fire it when the valves weren’t closed!")

Select model optimized for measurement(s):

Fluorescence & absorbance employs a UV optimized fused silica (Suprasil) 4 x 4 mm window [most common, smallest volume, shortest deadtime]

Absorbance & fluorescence employs a cylindrical optical-grade quartz window, 20 mm x 2 mm [classic design]

Circular Dichroism & absorbance employs a 2 mm cylindrical quartz observation cell [required for CD; not appropriate for fluorescence]

Absorbance Low Temperature has stainless steel interior with a 10 mm pathlength cell and syringes uniquely suited to -50° to 5°C use

Typical research areas include reaction mechanisms, drug-binding processes, and determination of protein structure. Other applications include:

Ligand binding

Coordination reactions

Chemical reactions

Electron transfer

Fluorescence resonance energy transfer (FRET)

Protein folding

Enzyme reactions

Protein-protein interactions

The first shot fills the tubing. The second shot gives partial kinetics. The third shot is the keeper. And the fourth shot confirms the third. All in all, a few hundred ul of solution are used. And, if the stopped-flow is used on an OLIS RSM 1000, all the data one needs are within these few shots, as each shot produces kinetics at over 200 wavelengths with millisecond time resolution.

How far back does our expertise in stopped-flow go?

Here’s the first publication citing computerized data acquisition from the laboratory which developed the Gibson/ Durrum/ Dionex stopped-flow.